Industrial Consulting

Mechanical Vibrations

|

| own frequencies of beams |

may be useful as e.g. vibrating screens. The correct choice of the vibration exciter is of great importance to maintain optimal process results

The inevitable residual vibrations should be put under control to ensure acceptable ambient conditions.

Performing an analysis of the own vibrations of supporting ceilings may be of great benefit.

Optimum maintenance

|

| Monitor with condition indication lights |

An exact knowledge of possible fault reasons and sources allows a tailored monitoring of vibrating machines.

Recording the operating conditions in a way similar to a black-box, i.e. long time recording and with higher resolution shortly before stopping the machine gives detailed information about the possible fault which triggered the alarm.

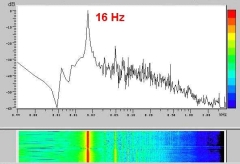

Infraschall

|

| A frequency analysis discovers the originator |

Non-hearable sound waves (under 20 Hz), also called air vibrations, are frequently emitted by vibrating machines and may cause annoyance such as nausea.

If a room resonance is excited, causing a "standing wave", this can propagate for long distances and thus causing discomfort in the neighborhood.

Eigenfrequencies

|

| Areas of stability/instability. Practical measurements confirm the physical theorems |

Not only natural frequencies in the neighborhood of the operating speed cause trouble, but also higher frequency values may lead - excited by the impulse of the conveyed material - to unstable conditions.

A measurement of the Eigenvalues before putting the machine in operation and performing the correct design modifications eliminate this danger.

Quality assurance

|

| Operating reliability is a product of quality assurance |

The specific design of vibrating machines makes it essential that other points of view shall be considered than those common in machinery concepts.

A founded knowledge of the essential parameters is the basis for quality criteria and acceptance levels, to ensure an optimal reliability of the machine combined with economical aspects.